| Contact Us | Quality Control | |||||

| About Us | Engineering | Mold Making | Custom Molding | Secondary Operations | ||

| Prototypes |

| Mold Design |

| Custom Mold Making |

| Custom Molding |

| Insert Molding |

| Over Molding |

| Automotive Parts |

| Molds for Automotives |

| Printing and Painting |

| Assemblies |

| Dropshipping |

| Outsourcing |

| Useful Links |

| DME Mold Components |

| www.dme.net |

| Hot Runners |

| www.yudo.com |

| ASSAB Steels |

| www.assab.com/en/ |

| Mold Bases and Steels |

| www.lkm.com.cn |

| Mold Flow Analysis |

| www.moldex3d.com |

| Chinese Mold Steels |

| www.fs-ss.com/en/ |

Our engineering services start from reverse engineering, through product design, design verification, mold design, etc. Thus, whether you have a completely new concept or you would like to improve existing design, we can offer perfect engineering and design services you need.

We use software including but not limited to Pro_E, Solidworks, UG, Moldflow, etc.

In-house Product Design and Development

Our engineering and design team involves in the entire developmental process of products to ensure the success of every project.

We can start projects from a simple sketch or an existing and incomplete sample. 3D models can be generated from samples through 3D scanning before we study and improve them to get cost-saving and customer-oriented solutions.

Reverse Engineering

Haida offers reverse engineering services to obtain the geometries and surface characteristics of parts.

Our engineers take advantage of the most precise metrology equipment available to scan offered samples and create 3D models to capture the objects of original designs with excellent precision. 3D scanned point cloud data will be converted to 3D models to provide customers with an analysis of their structure, function, etc.

For nearly 20 years, we are always servicing our customers with low-cost and short-lead time solutions.

Design Verification and Validation

Design verification and validation is critical to product development process. It helps us to ensure that products meet their expected purpose and function.

Haida offers comprehensive validation and validation services from design verification and validation to process capability studies. We tailor our services to meet your specific needs.

Machined Prototypes and 3D Printed Prototypes

Prototyping is essential in product development because it allows us to test concepts, refine designs, and identify potential flaws before going to formal production. Generally, we make prototypes by CNC machining or 3D printing. Each of them has its own advantages. We are experienced at both of them.

-Quickness: from concept to prototype

-Flexibility: low-to-medium prototyping volumes

-In-house engineering

-High quality

Moldflow Analysis

Moldflow analysis can study process before manufacturing molds. It helps analyze material characteristics and behaviors in areas like melt flow, pressure drop, fill time, increasing accuracy, etc.

With up-to-date software, our experienced engineers can identify problems and provide solutions in advance and have helped customers achieve countless improvements while creating innovations.

|

| (Design for Manufacturing) |

|

| (3D Printing) |

|

| (Machined Prototypes) |

| (Mold Flow Analysis) |

|

| (Mold Design) |

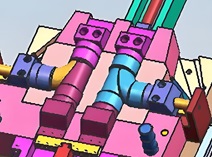

Mold Design

Our team has a deep understanding on product structures, molds and molding. We optimize mold designs for easy building, efficient production and cost-effectiveness.

Our team has extensive experience in designing various injection molds which include single-cavity molds, multi-cavity molds, family molds, hot runner molds and other molds with complicated structures. We aim to maximize productivity and ensure consistent part quality through perfect mold designs.