| Contact Us | Quality Control | |||||

| About Us | Engineering | Mold Making | Custom Molding | Secondary Operations | ||

|

|

|

|

|

|

||||||

| Part Desgin | Mold Building | Molded Parts | Painting | Printing | Assembly Line |

| Prototypes |

| Mold Design |

| Custom Mold Making |

| Custom Molding |

| Insert Molding |

| Over Molding |

| Automotive Parts |

| Molds for Automotives |

| Printing and Painting |

| Assemblies |

| Dropshipping |

| Outsourcing |

| Useful Links |

| DME Mold Components |

| www.dme.net |

| Hot Runners |

| www.yudo.com |

| ASSAB Steels |

| www.assab.com/en/ |

| Mold Bases and Steels |

| www.lkm.com.cn |

| Mold Flow Analysis |

| www.moldex3d.com |

| Chinese Mold Steels |

| www.fs-ss.com/en/ |

In the lasts 20 years, we offered thousands of molds and millions of molded parts for a wide variety of industries including Automotives, Electronics, Agriculture, Home Appliances, Automation, Communications, toys, etc.

Customer-oriented Engineering and Design

Haida has established an excellent engineering department to provide engineering services to a wide variety of clients.

Our engineering team can start projects from a simple sketch or an existing and incomplete sample. 3D models can be generated from samples through 3D scanning before we study and improve them to get cost-saving and customer-oriented solutions.

Whether you have a completely new concepts or you would like to improve existing designs, Haida can submit perfect solutions to them.

Machined Prototypes and 3D Printed Prototypes

Prototypes allow design verification and testing fit and detect costly errors before they become very time consuming and expensive issues.

We provide both traditional machined prototypes and 3D printed prototypes.

Mold Building

We design and build plastic injection molds in-house. Our facility is well-equipped with up-to-date equipment which includes CNC machining centers, EDM machines, Wire Cutting machines, etc. And, our workers are richly experienced with excellent craftsmanship.

For nearly 20 years, we are manufacturing a wide variety of plastic injection molds, which includes both simple 2-plate molds, complicated 3-plate molds with various mechanism, hot runner mold, etc.

The industries are servicing include Automotives, Electronics, Agriculture, Home Appliances, Automation, Communications, etc.

Plastic Injection Molding

For nearly 20 years, Haida keeps supplying high quality molded parts to customers in a wide range of industries.

We operate molding machines spanning from 65T to 800T and provide solutions for intricate-part molding, large-part molding, gas-assist molding, insert molding, over-molding and conventional injection molding, etc.

From prototype molding through full low- to high-volume production, we will work with your team to exceed your expectations on quality and delivery.

Secondary Processes

Haida has rich experience at secondary processes. These value-added services are designed to meet your specific needs.

The secondary processes we handle are as below.

*Painting *Printing *Post-mold machining *Heat staking *Plating

*Functional inspection *Custom Packaging

|

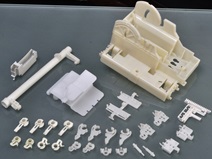

| (Molds Ready for Export) |

|

| (Custom Molding) |

|

| (Over Molding) |

| (Insert Molding) |

Assembly

Haida provides assembly solutions as part of our one stop service. It can save you time money by keeping these processes under one roof.

According to the different requirements of the finished product, we have several different methods as below to choose.

*Ultrasonic welding

*Adhesive bonding

*Solvent bonding

*Mechanical assembly

And, we have confidence that we can meets your demands.

Warehousing and Logistics

Haida supplies custom molded components to many OEM manufacturers. Our dedicated service team established and maintain an effective supply chain management system.

Haida maintains inventory of critical custom plastic components and deliver them in time as requested.

We have the capability to make delivery directly to our OEM client manufacturing lines on time to minimize or eliminate their on-site inventory of plastic components.

QC and QA System (ISO 9001 Certified)

Haida has established independent quality control and assurance system which controls every procedure including incoming material, mold making, molding, assembly, package, etc. Our quality standards are maintained by our experienced QA engineers and inspectors who monitor all aspects of our manufacturing operations.